OIBG Drop Rail

The drop monorail is a linear impact apparatus that enables drops to be performed from up to 3.0 meters with minimal friction. A rail carrier allows attachment of customized fixtures to constrain the impacted object to a single degree of freedom. One application of this apparatus is standardized helmet certification testing whereby a helmeted anthropomorphic headform is secured to the rail carrier and dropped from a prescribed height while measuring acceleration at the center of gravity of the head. Generally, the impact surface is a steel anvil but can be modified to represent different surface characteristics.

High-Speed Cameras

Two Phantom V9 cameras (Vision Research, New Jersey, USA) are used to record impact events at rates in excess of 9000 Hz. These CMOS-based cameras can collect at their full image resolution of 1600 x 1200 pixels at 1000 Hz. At lower resolutions the frame rate increases as shown in the table below. Using two of these cameras and appropriate marker tracking software, three dimensional kinematics of impact experiments can be calculated. The cameras were purchased through funding from the Canadian Foundation for Innovation New Opportunities program.

INSTRON TESTING MACHINE

® Instron Corporation, Canton, Massachusetts, USA

There is one biaxial servohydraulic Instron testing machine in the lab: model 8874 (right), used mostly for in vitro testing of the strength and stability of bones, implants and surgical techniques. The machine is capable of 25 kN / 100 Nm. and can be controlled by Instron or Labview software.

OPTOTRAK 3020 and CERTUS®

NorthernDigital Inc., Waterloo, Canada

The Optotrak 3020 and Certus (shown in Figure) are both an optoelectronic measurement systems consisting of a camera and controller unit that interfaces with a PC. The camera contains three CCD position-sensitive detectors that track up to 256 infrared LEDs on moving objects with an accuracy of 0.1 mm for vertical and horizontal directions, and 0.15 mm for depth. With at least three LEDs attached to a rigid body, the rotations and translations can easily be calculated from the marker position data.

SPINE MACHINE

A custom loading frame has been developed in the lab that can be used to apply pure moments in the testing of functional spinal units (FSUs; two or more vertebrae). The moment is applied with a dc servomotor through universal joints, with a torque sensor giving feedback for control purposes. A six-axis load cell can be mounted under the FSU to ensure the applied loads are pure moments. Currently, only one motor is available, but others may be added in the future. Motions are measured with the Optotrak so that the stability of the spinal segment can be determined. Applications include the analysis of inury effects and stability of implants.

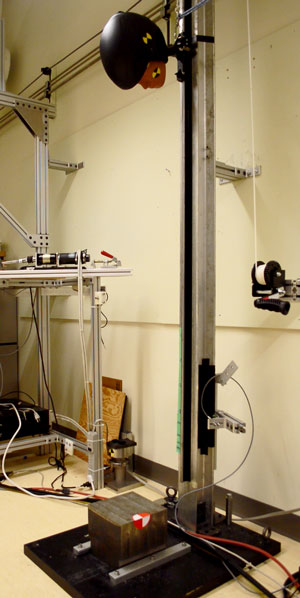

DROP TOWER

Many cervical spine injuries occur when the momentum of the torso must suddenly be stopped as a result of head-first impact into a surface (such as a pool bottom, the ground or the roof of a c motor vehicle during rollover. This situation can be simulated using our custom drop tower (below). Load cells are used to measure the force applied to the head during ground impact. A six-axis load cell is used to measure the reaction force at the base of the cervical spine, T1. This design allows the impact severity to be controlled by variable drop height. The construction of this device was supported by an NSERC discovery grant.

Hybrid III dummy head and neck

The Hybrid III anthropomorphic test device head and neck are used in impact experiments to characterize head and neck injury parameters. The device incorporates upper neck and lower neck six axis load cells, and tri-axial accelerometers and tri-axial angular rate sensors in the head.

Magnesium Headform

The magnesium headform is a type of anthropomorphic headform which is preferred for impact testing due to its energy transfer characteristics. Commonly used in variable helmeted impacts and low energy, unhelmeted impacts, this headform is used in many standardized helmet certification test protocols.